1. The nominal tensile strength of bolt material reaches 400MPa level;

2. The yield strength ratio of bolt material is 0.6; The nominal yield strength of bolt material reaches 400 × 0.6=240MPa level.

Performance grade 10.9 high-strength bolts, after heat treatment, can achieve:

1. The nominal tensile strength of bolt material reaches 1000MPa level;

2. The yield strength ratio of bolt material is 0.9; The nominal yield strength of bolt material reaches 1000 × 0.9=900MPa level.

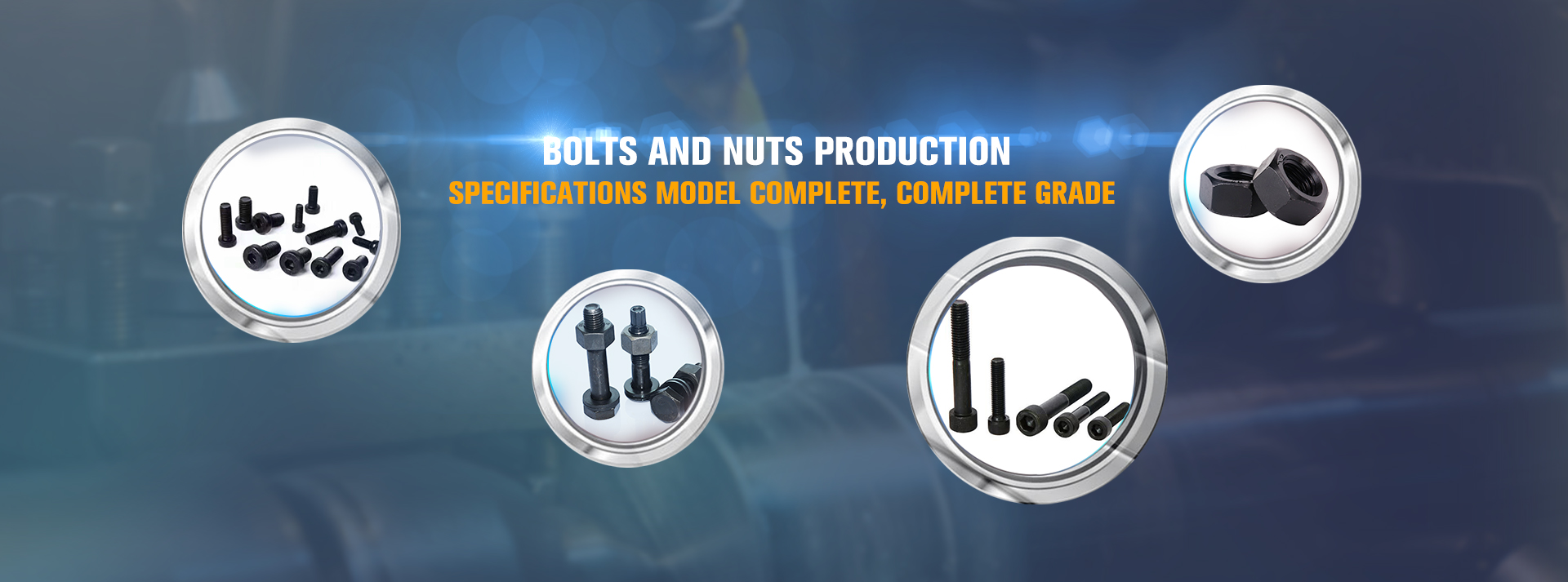

The meaning of the performance grade of internal hexagonal bolts is an internationally recognized standard. Bolts with the same performance grade have the same performance regardless of material and place of origin differences, and only the performance grade can be selected in design.

The classification of hexagonal bolts is basically like this, and the prices on the market will definitely vary depending on the grade. Generally, high-strength hexagonal bolts are much more expensive than ordinary hexagonal bolts. The four commonly used types in the market are 4.8 level, 8.8 level, 10.9 level, and 12.9 level.

The head of the hexagon socket bolt is eccentric and crooked, which may cause serious problems. For example, from the appearance of the product, it is not aesthetically pleasing overall. Another issue is that the punching is off center, which can easily cause the production tool to break easily. The most serious problem can also lead to a series of problems such as broken ends of the hexagonal bolts.

national standard

Cylindrical head hexagon socket screws comply with the national standard GB T 70.1-2008

Post time: Jul-02-2024